FCTUC researchers create a forest residue and fungi-based product that can be used in construction

A team of researchers from the Faculty of Sciences and Technology from the University of Coimbra (FCTUC) has developed a forest residue and fungi-based product that can be used in the field of construction, namely in interior walls of buildings.

The aim of this product, developed within the scope of the “Value2Prevent” project, is to value forest biomass, aggregate value to forests and, consequently, enable the increment of product yield.

“Usually, forest producers do not have big incentives to clean the fields, because the biomass that results from the cleaning has little value, given that it has to be transported to specific sites and that transportation and collection are costly. Therefore, a high return must exist, so that cleaning is compensatory for the producers”, begins by clarifying João Martins, researcher from the Centre for Functional Ecology (CFE) from the Department of Life Sciences (DCV) from FCTUC).

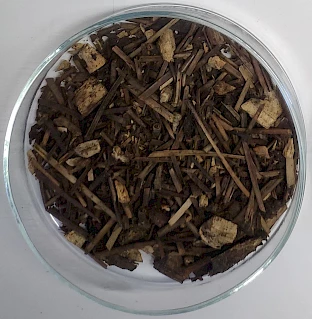

Following that, he proceeds, “we have developed a product that can be used in construction, namely in interior walls, that has a very interesting added value. The idea is to use the forest biomass residues, inoculate with a fungus that has the ability to partially degrade biomass, and create a kind of cement, by aggregating all the particles and forming a block. Posteriorly, this product is dried, to inactivate the fungus, and can be used inside two wooden plaques, replacing the synthetic materials currently used”, describes the researcher.

This product is not only a sustainable alternative, but it also has other advantages that can make the difference, namely “its thermic and acoustic proprieties, the fact that it is a more balanced option, because it is as sustainable as wood but as efficient as a synthetic coating, and besides, it is a low-cost product. Biomass is relatively cheap and we can produce these blocks easily”, he concludes.

The tests have been carried out using trees such as eucalyptus, maritime pine, strawberry tree, and even a mix of shrubs, but in the future, the team intends to test the use of other products with biomass, for instance, reused plastic, cork, and rubber, which can make the thermic and acoustic properties of this material even more efficient.

The project “Value2Prevent” is promoted by SerQ – Centro de Inovação e Competências da Floresta, having as partners the University of Coimbra (UC), the Instituto Superior de Agronomia (ISA), the Centro Ciência Viva da Floresta de Proença-a-Nova (CCVF), and Proentia – Essential Oils.

(Original press release elaborated in Portuguese by Sara Machado, FCTUC)